Details of MIG Machines

The two base materials are bonded via MIG welding, an arc welding process, using a continuous solid wire electrode. The welding cannon may discharge argon or argon plus carbon dioxide to further isolate the weld pool.

MIG welders are used in homes and businesses. Their versatility and ease of usage make them

ideal for welding stainless steel, aluminium, and steel.

Industrial-grade MIG welding equipment is suitable for fabrication, manufacturing, car repair,

construction, and other heavy-duty industries that need high-quality, high-production welding.

Modern MIG welders have pulse welding, synergic control, and numerous welding programmes. These

traits improve control, efficiency, and weld quality.

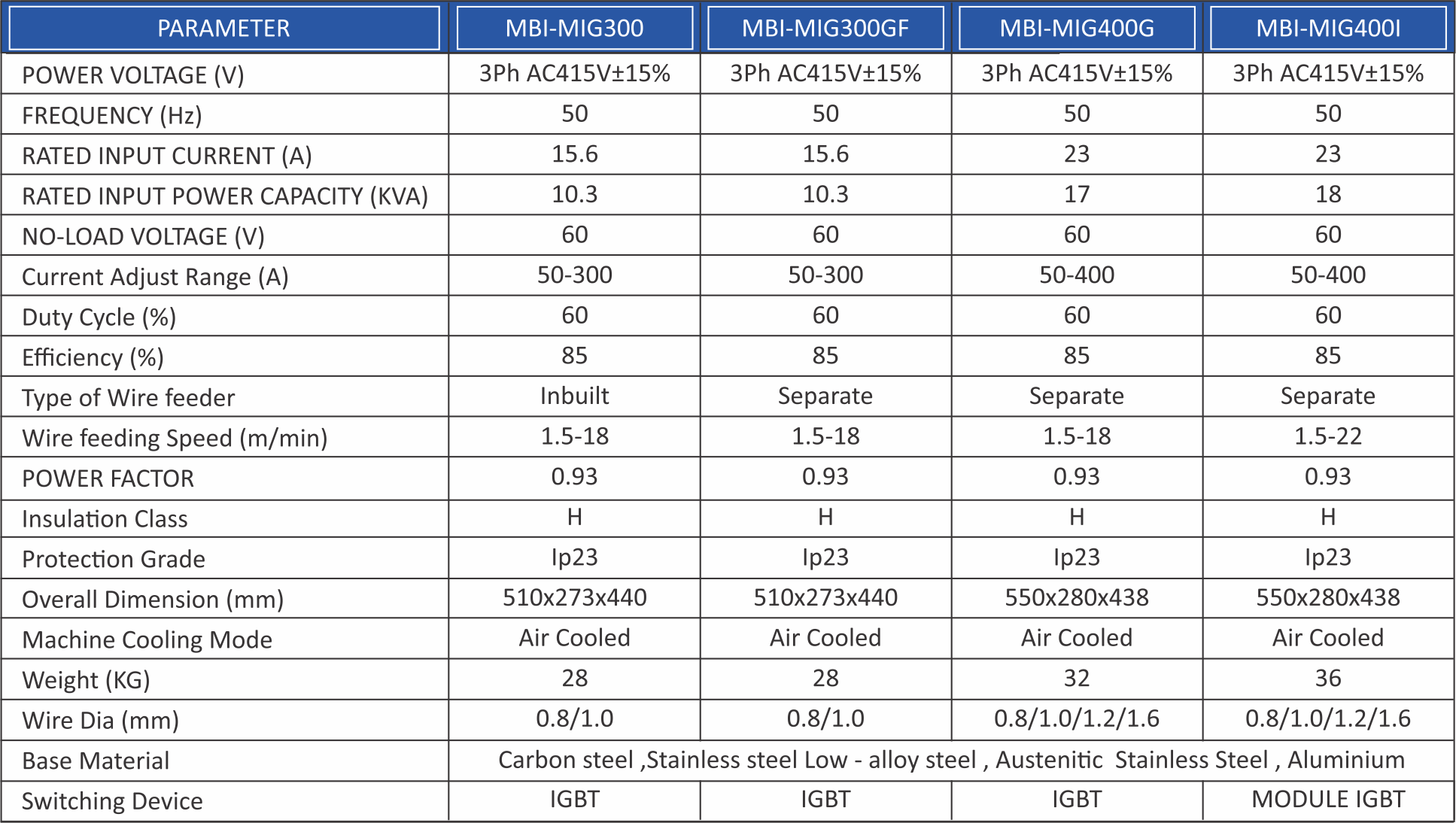

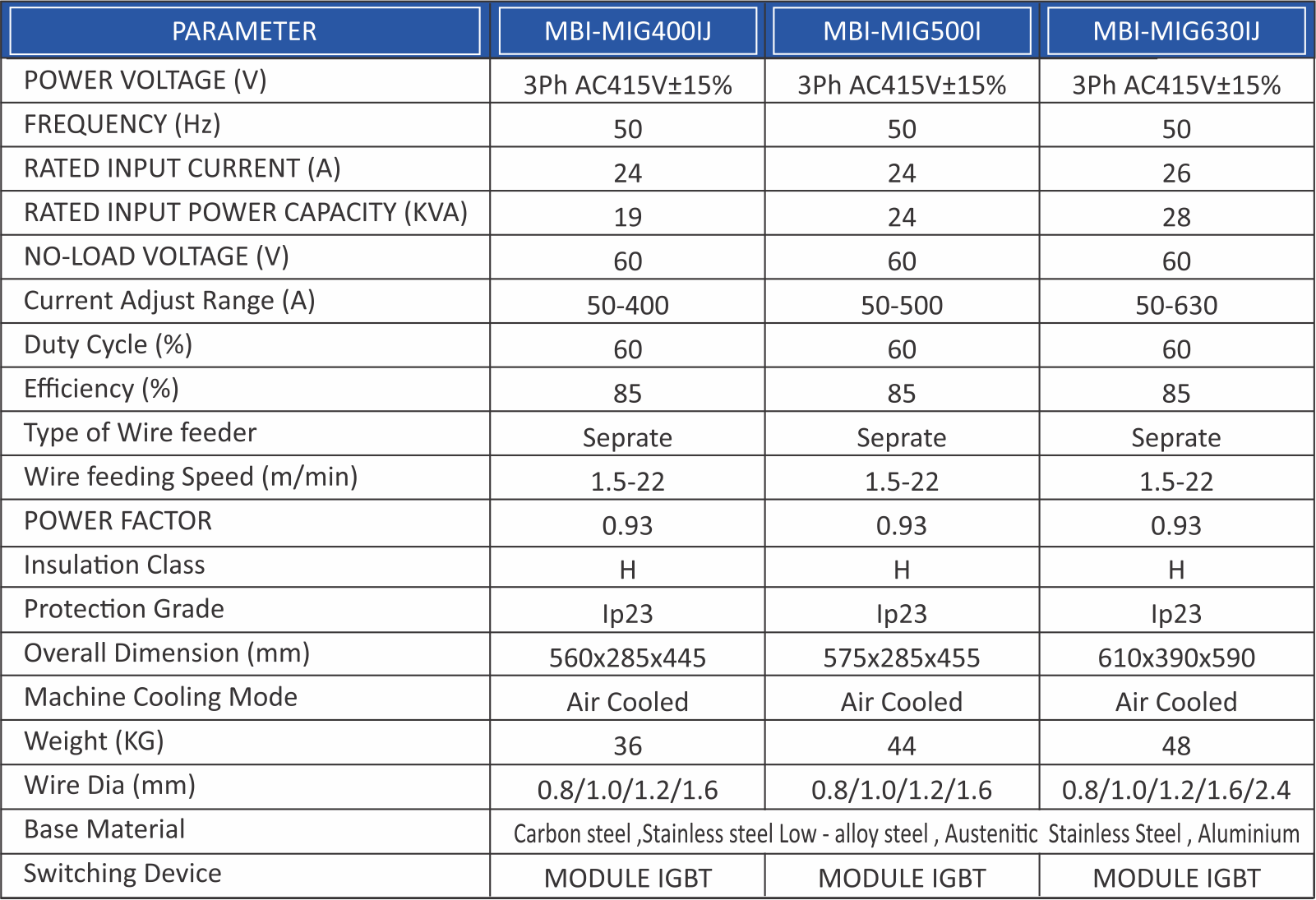

Different MIG welding machine manufacturers: Welding equipment manufacturers may have their own

MIG welding machine line. The varied models in this series may have varied features, power

outputs, and purposes.